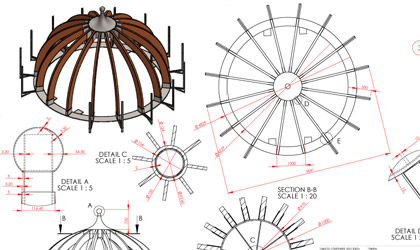

Windmill Glulam Dome

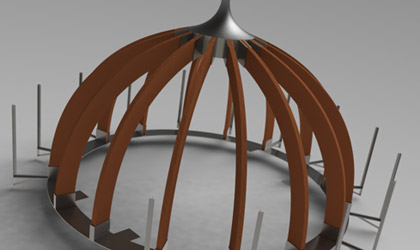

A bespoke glulam dome was to be fabricated, to sit atop of a 18th century windmill, for conversions into a domestic dwelling.

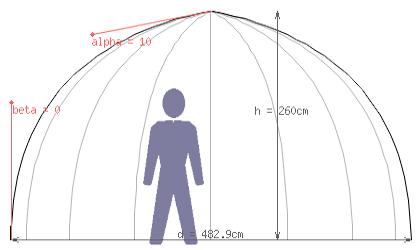

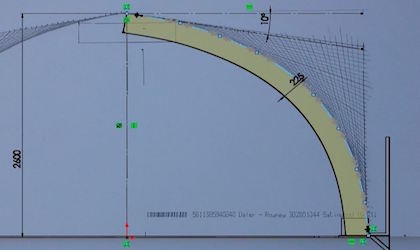

Design was initially commuicated verbally, through written design intent, photos, a physical model & hand-drawn sketches. As the 3D design took shape, specifics of connecting components & structural elements were tied down. Finally, an equation driven composite curve was extrapolated for the beam production.

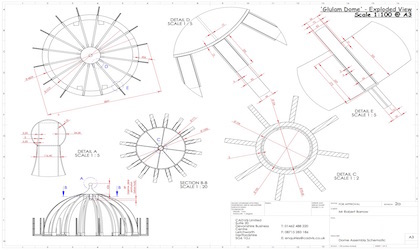

A detailed set of orthographic drawings were produced, fully annotated and showing interfacing components, a 'bill of materials' & exploded assembly diagram.

Post-hoc revisions were accomodated as required; the 'deliverables' were jpgs & pdfs for the 2D drawings and 'stp' files for CNC cutting.

Projects ranging from office, retail and space planning, virtual 3D builds of construction systems to 3D modeling of components & assemblies. We have accumulated years of invaluable experience working on CAD projects with large commercial organizations and small companies, inventors, entrapreneurs & property developmers.